Revolutionizing Electronics Manufacturing: The Impact of AI Technology

Revolutionizing Electronics Manufacturing: The Impact of AI Technology

Table of Contents

- Introduction to AI in Electronics Manufacturing

- The Role of AI in Automating Manufacturing Processes

- AI-Driven Quality Control in Electronics Manufacturing

- Predictive Maintenance and AI

- Enhancing Supply Chain Efficiency with AI

- The Future of Electronics Manufacturing with AI

- Conclusion

Introduction to AI in Electronics Manufacturing The integration of Artificial Intelligence (AI) has significantly transformed the electronics manufacturing industry. It’s not just about automating processes; AI is redefining how electronic components and devices are conceptualized, designed, and produced. This article explores the multifaceted impact of AI in electronics manufacturing, highlighting key areas where AI is making a substantial difference.

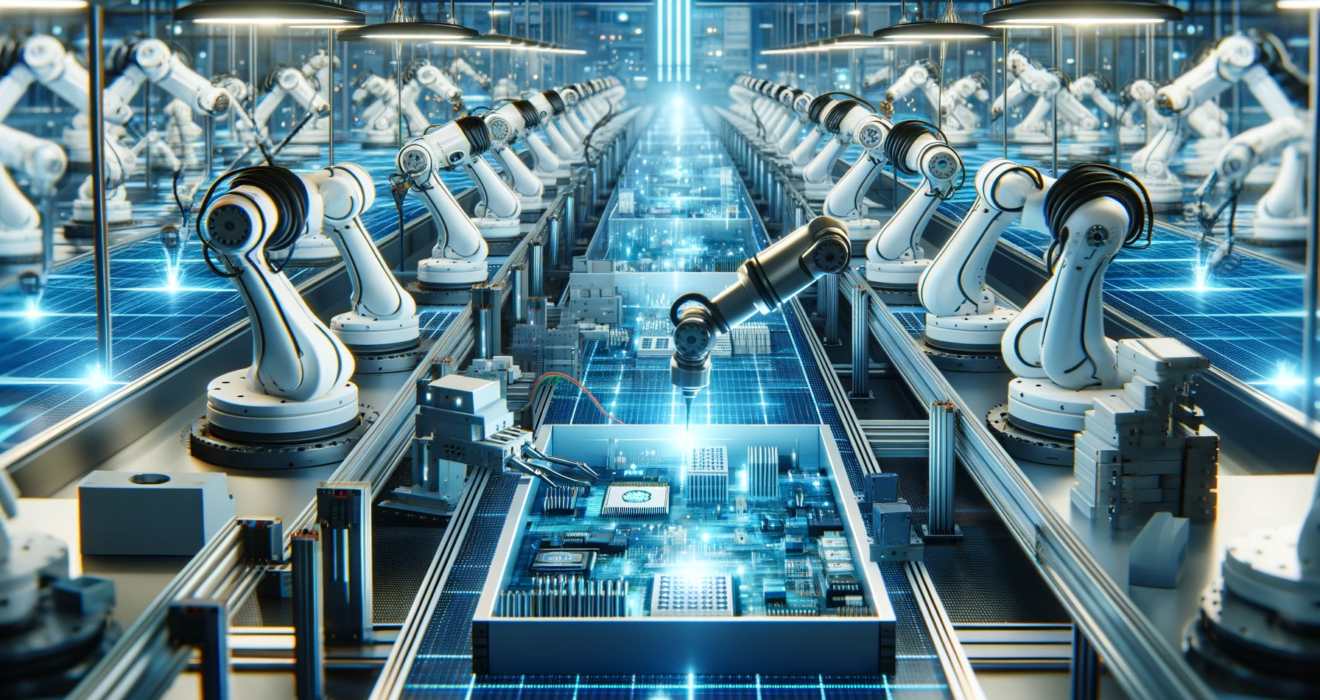

The Role of AI in Automating Manufacturing Processes AI’s most noticeable impact in electronics manufacturing is the automation of production lines. AI-driven systems control machinery with unprecedented precision, significantly reducing human error and enhancing production efficiency. For example, AI-powered robots are now performing intricate tasks such as soldering and assembly, which traditionally required skilled labor. This shift not only streamlines operations but also leads to substantial cost savings and resource optimization.

AI-Driven Quality Control in Electronics Manufacturing Quality assurance is a critical component in electronics manufacturing. Leveraging AI technologies for inspecting and detecting defects has proven to be far more effective than traditional methods. With advanced image recognition and machine learning, AI systems can scrutinize electronic components at an exceptionally detailed level, identifying minor imperfections that might be overlooked by human inspectors.

Predictive Maintenance and AI Predictive maintenance is another area where AI is making significant inroads in the electronics manufacturing industry. AI algorithms analyze data from various sensors and machines to predict potential equipment failures before they occur. This proactive approach not only reduces downtime but also extends the lifespan of manufacturing equipment, ensuring more consistent production quality.

Enhancing Supply Chain Efficiency with AI AI is also revolutionizing supply chain management in electronics manufacturing. By analyzing large volumes of data, AI can forecast supply and demand trends, optimize inventory management, and identify the most efficient logistics routes. This leads to a more responsive and flexible supply chain, capable of adapting to changing market dynamics swiftly.

The Future of Electronics Manufacturing with AI Looking ahead, the role of AI in electronics manufacturing is set to grow even more influential. We can anticipate more personalized and agile manufacturing processes, where AI-driven systems adapt to produce customized products quickly. The integration of AI with other emerging technologies such as the Internet of Things (IoT) and 5G is poised to create even smarter and more interconnected manufacturing ecosystems.

Conclusion The influence of AI in electronics manufacturing is profound and all-encompassing. From enhancing production efficiency to revolutionizing quality control and supply chain management, the contributions of AI are pivotal. As AI technology continues to advance, we can expect even more innovative and groundbreaking changes in electronics manufacturing, driving the industry towards greater efficiency, precision, and innovation.