X

About Us

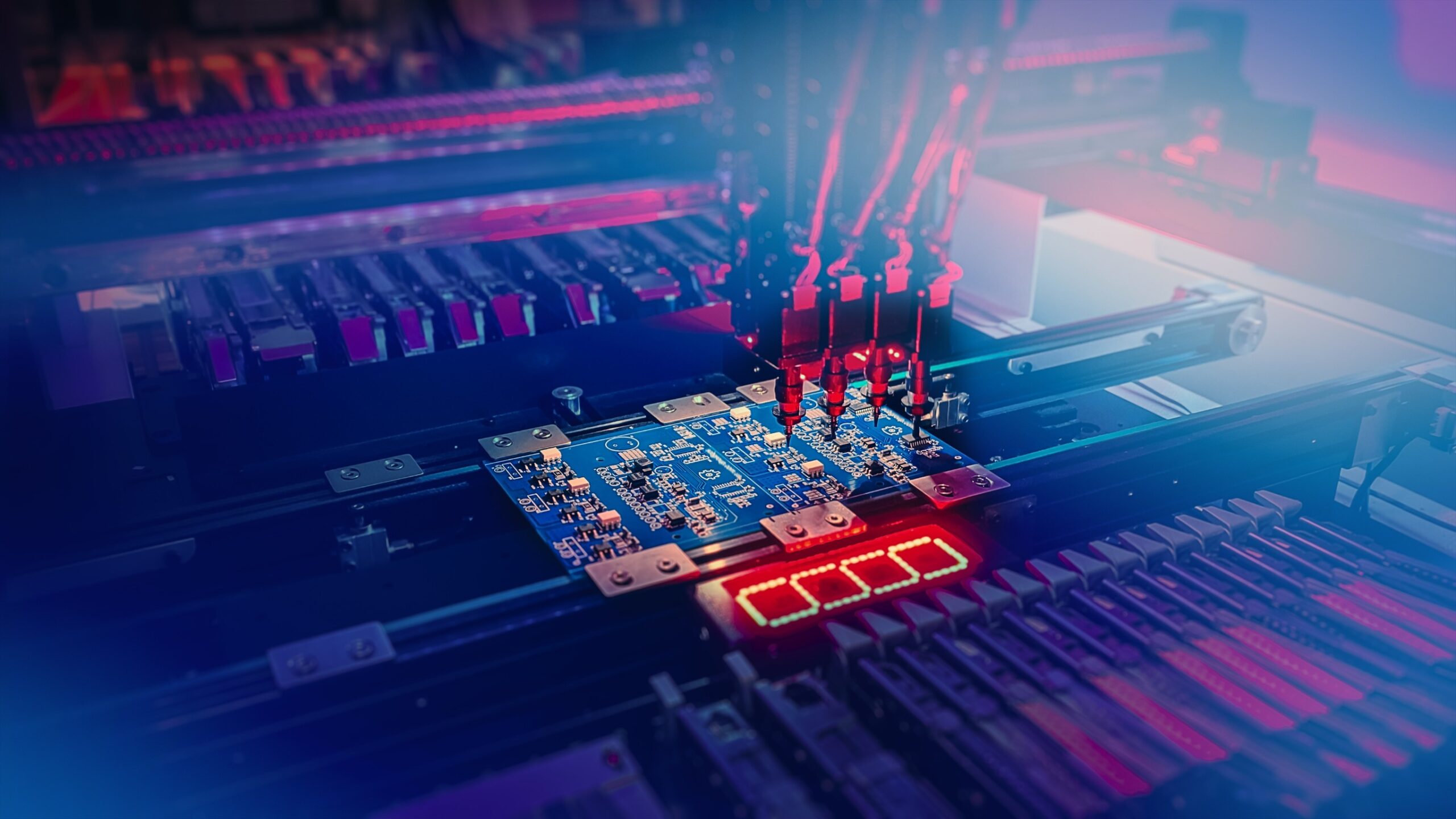

Innovative Solutions in Electronics Design and Production

AET Electronics specializes in delivering innovative solutions in electronics design and production, combining cutting-edge technology with expert craftsmanship to meet diverse industry needs.

Contact Info

- OSB 5. Cadde No:42 Sivas TURKIYE 11417 Irving Park Rd, Franklin Park, IL 60131 U.S.A.

- info@aetelectronics.com.tr

- + 90 533 724 54 83